Lambha, Ahmedabad, Gujarat

- GST NO. : 24HMHPS0840A1ZC

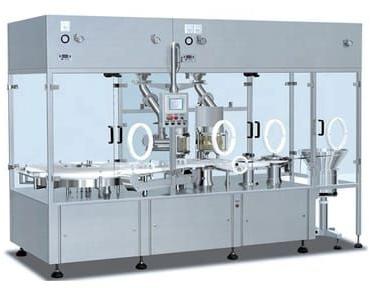

Production Line

Leading of Automatic IV Fluid Bottle Packing Line, Dry Powder Filling Machine and Injectable Liquid Vial Filling Line from Ahmedabad.

| Business Type | Manufacturer, Supplier |

| Driven Type | Electric |

| Color | Silver |

| Automatic Grade | Automatic |

| Country of Origin | India |

| Model No | HPM-IV-120 |

| Bottle/ Minutes | 120 to 240/ Minutes |

| All non-contact | SS304 |

| Srencture | Heavy Duty |

| Electrical Details | 415V, 50Hz |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Voltage | 230V |

| Country of Origin | India |

| Filling Material | Powder |

| Usage/Application | Packing Industries |

| Material | Stainless Steel |

| Phase | Single Phase |

Preferred Buyer From

| Location | Anywhere in India |

Auger fillers use load cells and balances to control the fill level. The system can operate in feedforward, bulk, or setpoint modes. In feedforward mode, the auger runs at a high speed for the most of the fill before slowing down to dribble pace for the last bit of the fill.

A dry powder filling line is made up of a variety of devices that may control the fill weight. In the designs of these devices, load cells and balances are frequently used. These devices may be able to control weight in one of three ways, depending on their configuration: setpoint, bulk, or feedforward. In setpoint mode, the auger fills at a quick rate for the majority of the time before dribbling slowly.

Either an automatic or semi-automatic filling line is available. For lighter weights, semi-automatic filling lines are appropriate. Two weigh cells are required on a filling line in order to achieve zero error in volumetric filling. While the other measures filled bottles, the first weighs empty bottles. The fill weight is the difference between the tare weight and the gross weight.

There are two categories of bulk dry powder filling lines: automatic and semi-automatic. The automatic kind fills dry powder bottles using a single head auger. Semi-automatic fillers don’t need someone to work by hand. They may be set up in one step or two steps.

An auger that turns a hopper is a component of semi-automatic auger fillers. This machine is simple to maintain and is built to provide extremely accurate fills. The hopper and auger are both constructed of stainless steel. Sensors also aid in controlling the flow of powder into packing.

Double head dry powder filling Machine are incredibly adaptable and can accommodate a wide variety of powders. They have two distinct filing heads that cooperate to fill each bottle evenly and consistently, as opposed to a filler with a single head. They can handle numerous fills each minute depending on the amount of powder and might be a terrific, cost-effective solution for your company.

Any size of production plant can instal single- or double-head filling lines. They are appropriate for businesses in the pharmaceutical, food, biotech, and agricultural sectors. Due to its small size and construction in corrosion-resistant stainless steel, they require little maintenance and have a long service life.

High levels of automation are seen in robotic filling and capping equipment for dry powder filling lines. They can also be created to fulfil particular customer requirements. They are perfect for usage in pharmaceutical, nutraceutical, cosmetic, and food goods and can be used with a variety of closure styles.

Pharmaceutical powders are an essential part of many drugs, such as antibiotics and painkillers. Filling medications in liquid form is challenging enough, but when utilising powders—which are significantly more abrasive—the difficulties rise. The amount of dust produced by the finely ground active substances can be very dangerous for machine workers.

A filling line is made up of several different machines. While some are operated manually, others are entirely automated. Some even have an integrated weigher to provide the most precise filling. The most crucial choice, regardless of the filling line type, will be which tools and drives are ideal for your individual requirements. The amount of powder in a certain container must be precisely measured before filling.

To create pharmaceutical dosage forms that are fully compliant with new requirements, a dry powder filling process can be constructed. Straight-line layouts are possible for these devices, which reduce cross-contamination and preserve aseptic standards.

Dry powder filling Machine comes in many distinct varieties. The Automatic Injectable Powder Filling Machine is one of them; it’s a small model made for filling vials with dry powder.

| Business Type | Manufacturer, Supplier |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Automatic Grade | Fully Automatic |

| Power | 3 HP |

| Voltage | 380V |

| Country of Origin | India |

| Vial Diameter | 15mm to 50mm |

| Vial Height | 75mm Maximum |

| Yield Capacity | 100-400 vials/min |

| Usage | 2-30ml vials |

| Depyrogenation temperature | 300-350°C |

| Filling error | ≤±2%( peristaltic/ ceramic/stainless steel pump drived by mechanical system) |

| Qualified stoppering rate | ≥99% |

Preferred Buyer From

| Location | Anywhere in India |

INJECTABLE VIAL LIQUID FILLING LINE

Complete line of Injectable Vial Liquid Filling line including Automatic Injectable Liquid Filling With Rubber Stoppering Machine, Automatic Aluminium Vial cap sealing machine, Automatic Online Visual Inspection Table, Automatic Round Container Self Adhesive (Sticker) Labelling Machine, Vial liquid filling machine, Packing Conveyor Belt with speed available different model 20 vail per minute to 400 vail per minute depend suitable line machines.

DESCRIPTION :

The compact vial line is consist of series vials washing machine, circulating heated air sterilizing tunnel and liquid filling and stoppering Machine for vial. And each machine can be used as unit alone. It is apply for filling 2-30ml vial, it can achieve the processing such as ultrasonic washing, three time water rinsing (two time circulating water , one time WFI water), three-time air spraying, sterilizing and dehydrogenation, cooling, Liquid filling, protection gaseous filling (nitrogen),and stoppering.

FEATURES

- Mechanical gripper holds the vial around the washing machine, applied to different size of vials.

- Bottle does not stop while washing process, the water and air nozzle following the moving Bottle and insert into vial, good quality washing effect, and WFI economy.

- The circulating water pipe and fine washing water pipe is separated fitted, there is no cross-contamination.

- Add buffering block in front of the spiral screw to prevent vial broken and protect the spiral screw.

- Bottle out-feeding section is adopted cellular-belts to transfer bottle, it is more stable and reliable.

- Circulating heating air exert on the vial while sterilizing, excellent temperate distribution, energy economy.

- Protecting for HEPA while power failure suddenly, safe running.

- Water cooling system is optional; it can decrease fresh air supply from the washing room, and reduce the risk from wind differential pressure imbalance, good cooling effect.

- Wind differential pressure auto-balance system is optional, it can make the air flow from heating section not move and steady , and it can avoid series trouble ,such as the temperature getting increasing in filing room and washing room.

- Vial Filling machine is adopted horizontal type cellular-belts to transfer bottle, it is fast and accurate, and easy to change format for different size of vial.

- There is certain distance between machine table and the plane which bottom of the vial situated, it is easy for wind of laminar flow crossing, and prevent the liquid contamination from turbulent flow.

- Adopt the horizontal stopper feeding at Stoppering station, and use horizontal disk to inhale and hold stopper, it is easy to observe and add the stopper, and feature of high speed feeding.

- For vial filling and sealing machine, the ceramic pump, SS pump, creeping pump is optional.

- Stop filling if there is no vial; stop stoppering if there is no vial.

- Servo system to be optional for filling (Delta, Mitsubishi, Rockwell).

- For vial filling and sealing machine, the servo system is optional for driving filling pump.

- PLC control the whole machine, inverter and touch screen is used in control system, so the machine is stable and reliable during running. The touch screen can display running status of all unit machine, water pressures, gas pressures and Temperatures of all controlled point, can display the status of all switches and its faults, faults self-diagnosis, faults analysis and its solutions. the Washing-sterilizing-filling and sealing inter-linkage balancing device, All of these make the compact line in automatic control, and makes producing process stable and reliable. Siemens, Rockwell, Mitsubishi or Delta is optional for the electrical control system.

- getting filling sample in place, mean the operator can get the filled ampoule periodically from the filling machine, while machine do not stop.